The next-generation sawmill

- News

A digital representation of the complete sawmill workflow, large amounts of data and new automated processes. With its new grading mill in place and the B700 project successfully completed, Bollsta Sawmill is equipped and ready to face the future. In the very place where the story began over 200 years ago, the foundation is being laid for the next generation of sawmills.

When we think of digitisation, we think of vast server halls full of blinking LEDs, of e-invoices and advanced e-meeting tools. Similarly, heavy machinery, conveyor belts and manual labour are still associated with industry. This somewhat outdated image no longer corresponds to reality, not in Bollsta at least. With all of the pieces of the project puzzle in place, with an unrivalled grading mill and some of the most advanced technology on the market SCA is now ready to develop the sawmill of tomorrow.

“In the B700 project and the investments in technology it involves, I can affirm that we have laid the foundation for the next generation of sawmills. A considerably more digital sawmill in which no element of our manufacturing process need longer be left to chance,” says Johan Olofsson, technology and operations development manager at SCA Wood and director of the B700 project.

3D models improve sorting and increase yield

This has been made especially clear by the CT scanner installed at the log sorting station as part of the project. Where once the sawmill relied on a visual inspection of the exterior properties and shape of a log, Bollsta is now one of the few sawmills in the world with the capability of creating added value by sawing logs based on images of their interiors.

“The logs we saw have often been growing in the forest for between 70 and 100 years and the fact that we can now see straight through them using advanced imaging technology is a real game-changer. It means that, before we saw the log, we can decide which product it is best suited to and no longer leave any aspect of our manufacturing process to chance. In combination with the increased production capacity of the grading mill, this gives us a genuine competitive advantage,” says Olofsson.

Full traceability along the entire chain

The CT scanner and its fingerprinting technology also enables SCA to follow the logs journey through the sawmill, from sorting to finished product in the warehouse. In other words, by giving every log a unique ID, we can now follow all pieces back to the exact log they were sawn from, a technical development that allows us to control and follow up the finished product at a completely new level.

“With the new grading mill in place in Bollsta and all of the new technology operating in other parts of the sawmill, put simply, we now have a unique opportunity to create a fully digital representation of our entire workflow. We can now run a virtual copy of production in parallel with the real one, and work with optimisation in an entirely new way,” continues Olofsson.

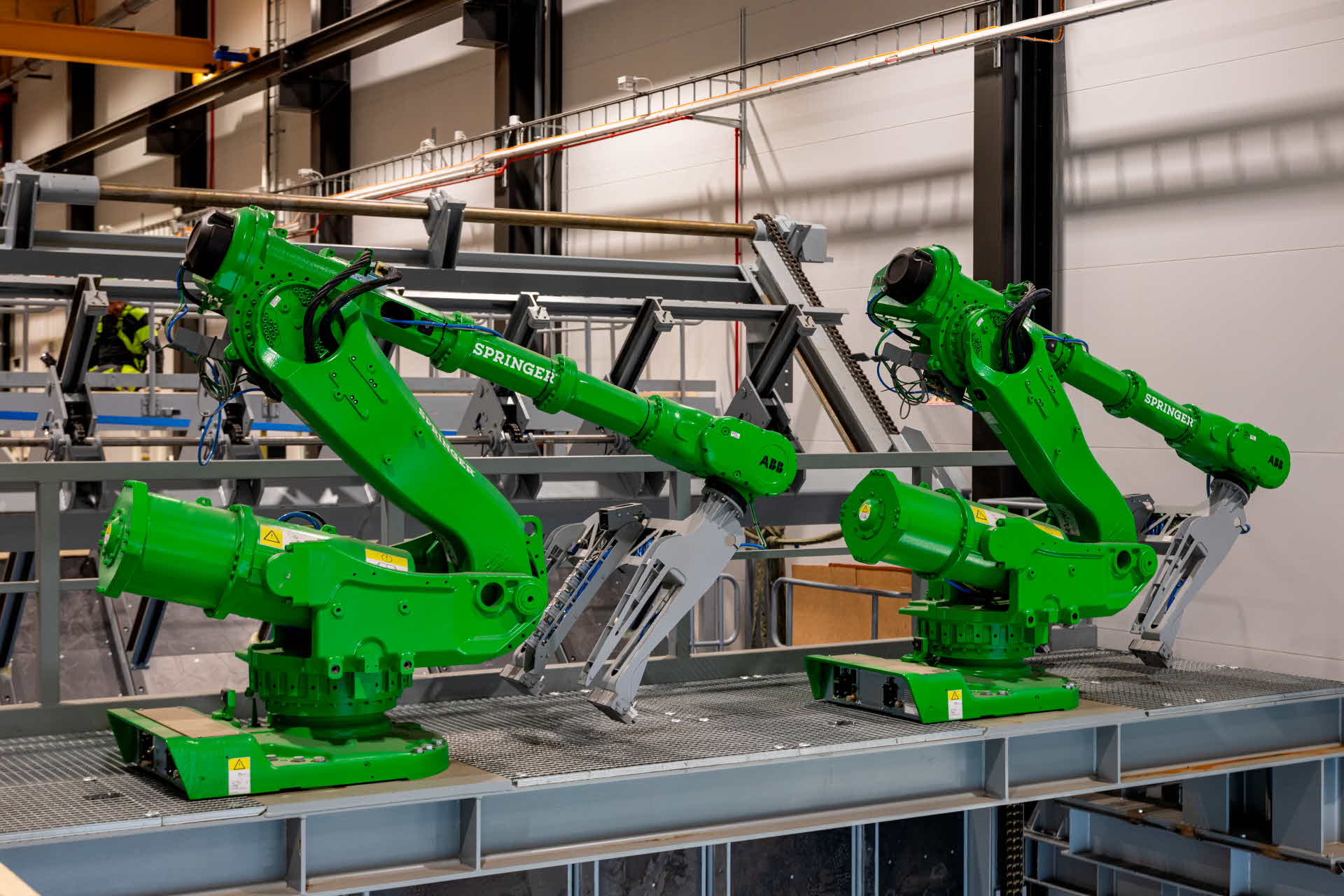

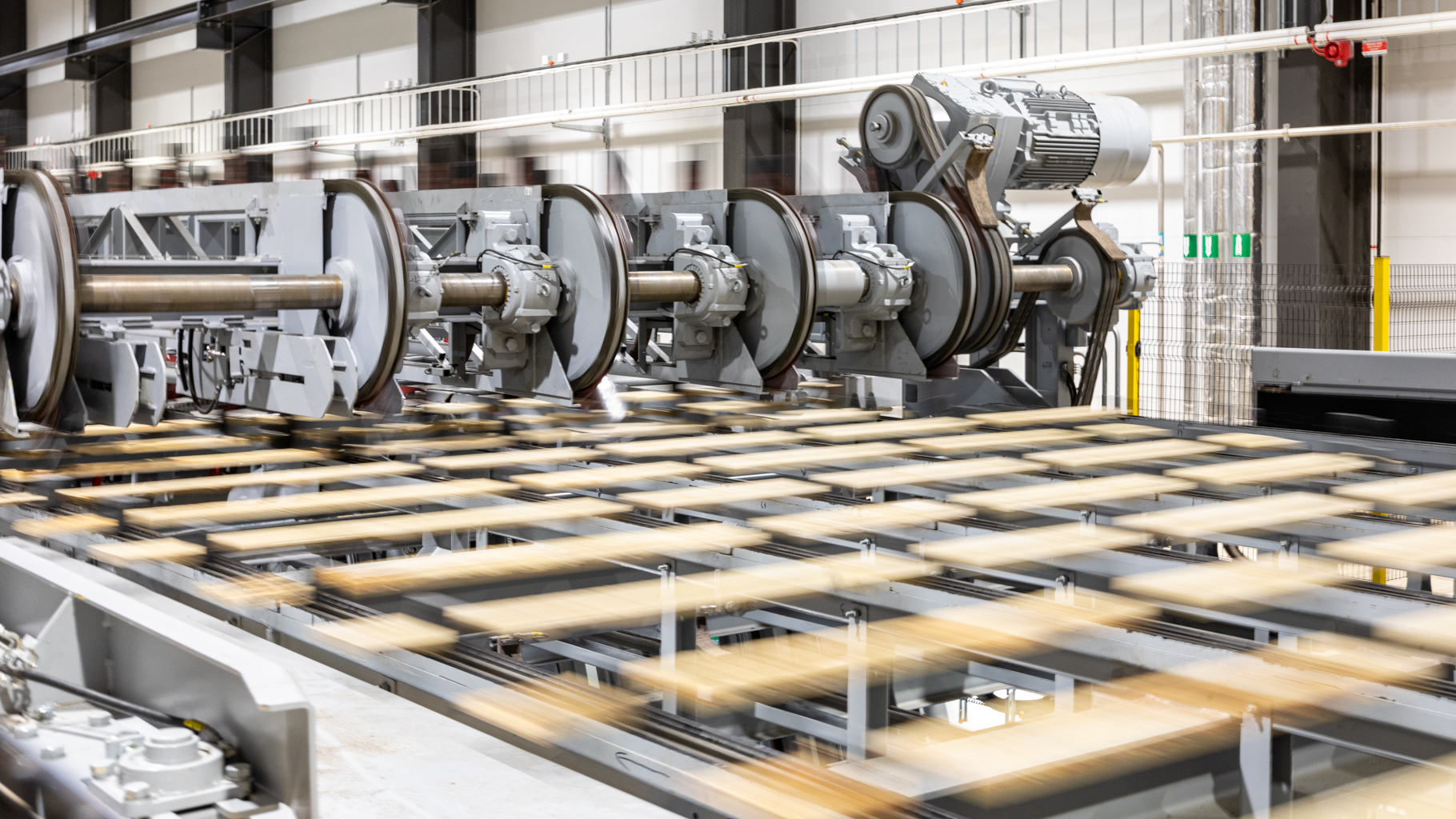

Parts of the new equipment in operation.

Large amounts of new data provide new conditions for development

As a result of the interconnectedness of the components of the new mill, and thanks to the fingerprint technology, an enormous amount of new data is being generated. Staff can use this data themselves and, eventually, with the help of computer use it to develop the organisation much more quickly and efficiently.

Using the data that has been registered and stored, among other things one can follow up any problems that might have arisen at one’s leisure, as well as analysing any patterns and use machine learning to identify potential problems before they happen. At least, this will be possible before too long.

“A computer that has seen an operator take the same measure to fix a given problem often enough will be able to issue a warning before anything happens, or propose solutions much more quickly and, eventually, fix the problem itself when it does arise,” explains Olofsson. “Just as in other areas of society, we see enormous potential in being able to further digitise our processes. At Bollsta Sawmill, we are now taking advantage of all the technical aids currently available, while at the same time preparing for what we believe will be possible tomorrow. Anything to create even more value from the forests we harvest.”