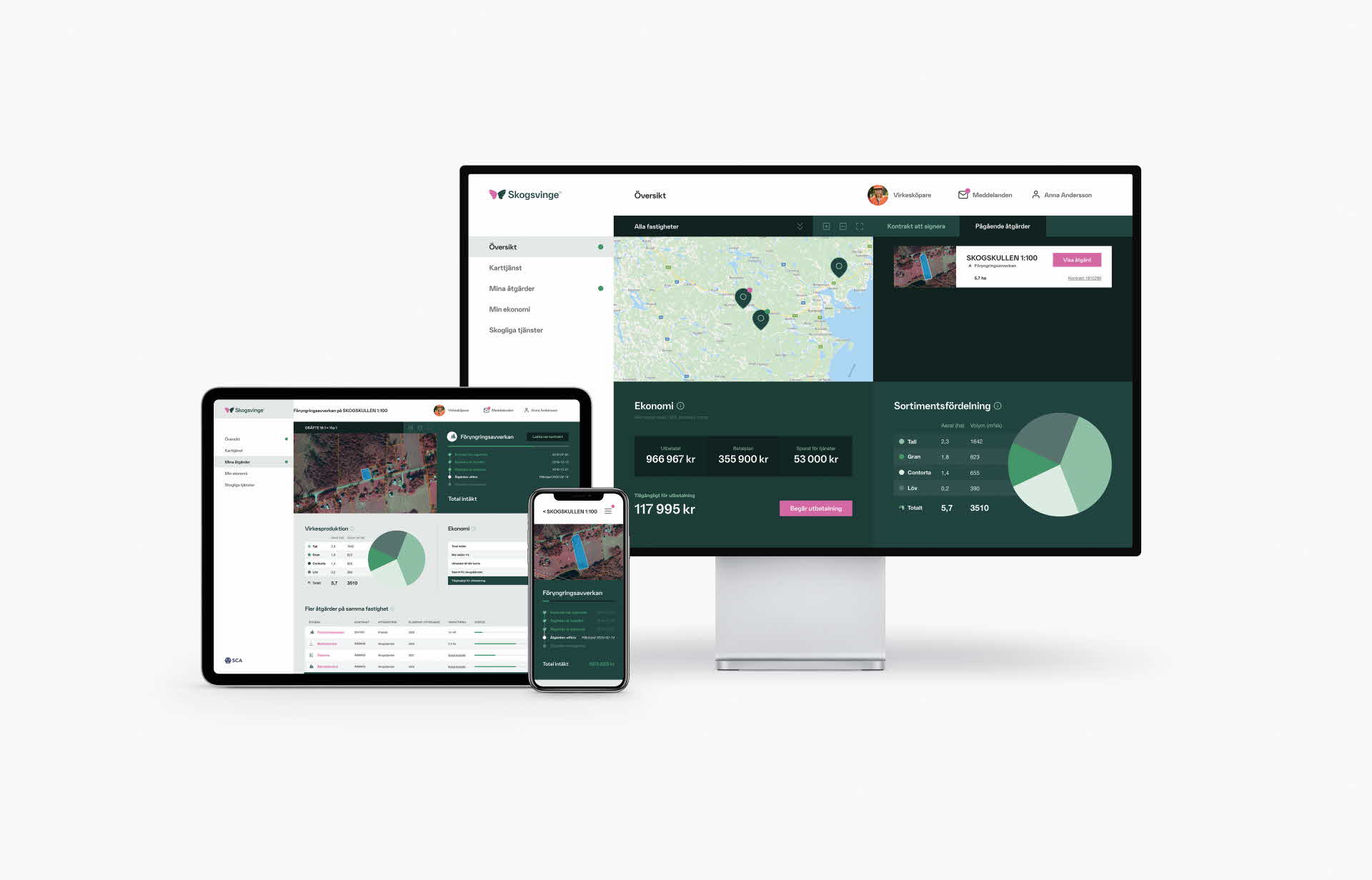

SCA's digital service Skogsvinge moves the forest to the forest owner, and forest owners can manage their forest and forest business remotely. Skogsvinge combines and analyzes facts about the forest so that forest owners can monitor forestry at a detailed level. In this way, the forest becomes accessible regardless of where you are.

- ABOUT SCA

- INNOVATION AND RESEARCH

- FOREST INNOVATIONS

Innovations for a sustainable forestry

Innovative cooperation with different partners contributes to develop our forestry. Our projects include digitalized services for both technical and machine development. The goal is to reach an efficient and sustainable forestry and value-creating service offerings to forest owners.

Technical development for a sustainable forestry

SCA's ambition is to be at the forefront when it comes to testing new technology to develop sustainable machine and driver solutions and to help drive the development towards fossil-free transport. Here we present some exciting collaborative projects.

Geofencing

SCA and the Swedish Transport Administration are now testing geofencing in about 40 timber trucks that travel along selected roads in Jämtland and Västernorrland. With gps technology the vehicle's speed automatically reduces when they enter a specific area. In this way we can ensure safer timber transport.

Electric timber truck

SCA and Scania have together developed the first electric timber truck with a technical capability of up to 80 tonnes total weight. The vehicle is a sustainable transport solution and another step towards fossil-free society.

Centipede

The concept machine Centipede has been developed by SCA, seven other Swedish forestry companies and the forest machinery manufacturer Komatsu. The goal is to have a machine that combines lower soil compaction, increased productivity, and better operator environment.

Autoplant

Autonomous soil scarification and planting is fully feasible. This has been demonstrated by the joint Autoplant project. SCA is one of the participants. The idea is that the technique will provide a better working environment and higher precision, and reduce environmental impact.

Remote-controlled soil scarification machine

SCA is involved in a development project aimed at a remote-controlled soil scarification machine. Skogforsk leads the project and is responsible for the work in the testing environment, while SCA acts as the landowner and contributes with a base machine.

Services for making it easy to be a forest owner

We develop services that make it easier for private forest owners and that helps them in their forestry.

Skogsvinge

Hylosafe® protects seedlings

Hylosafe is SCA's proprietary long-acting environmentally friendly tree plant protection. It consists of a mixture of sand and binder that gives the plant good protection against beetles because it prevents them from eating on the plants. Hylosafe increases the chance of a good regeneration, with seedlings that survive and can grow up into new forest