- ABOUT SCA

- INNOVATION AND RESEARCH

- RESOURCE SMART PROCESSES

SCA part of the business research school Resource Smart Processes

SCA, through its R&D Centre, has participated in the Resource Smart Processes collaboration since its inception at the turn of the year 2021/2022. A business research school that is a national initiative and has been financed by participating industries, academia and the state innovation agency Vinnova.

The initiative has broad support among Swedish forest industry companies. The purpose of starting the business research school was to further develop today's processes in the forest, textile and chemical industries to become more energy efficient and resource efficient. SCA's main motive for investing in Resource Smart Processes is to contribute to future skills supply by training more students in areas that are relevant to our industry.

“The most important reason for our participation has been to ensure senior skills and to contribute to employees in the forest industry who have skills in the processes that generate revenue today and tomorrow,” says Jerker Jäder, Head of Research at SCA R&D Centre.

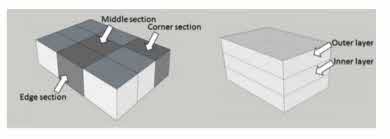

A partially delignified chip is cut into pieces to identify and analyze effects in parts of the chip. Delignification is a chemical process to release the substance lignin. Bild: Chalmers.

Different research directions

Several doctoral students are working in areas of direct interest to SCA. This research is carried out at Chalmers in Gothenburg, KTH in Stockholm and at Uppsala University.

Chalmers University of Technology

At Chalmers, the research is focused on identifying what is the bottleneck in the hardwood cooking process. There can be several reasons for this, such as the transport in of chemicals, degradation reactions in the process, or the transport out of dissolved material.

One doctoral student's work has focused on the transport in the fiber wall. One conclusion is that the outward transport of dissolved lignin, rather than the inward transport of cooking chemicals or reactions to release lignin, is rate-limiting. In the other work at Chalmers, the transport in the entire piece of woodchip has been studied. Among other things, wood chips have been examined with X-rays while being cooked, which has made it possible to see in real time how the lignin structure around and in the fiber is loosened during cooking. It will be interesting to see what conclusions can be drawn from this.

KTH Royal Institute of Technology

At KTH, research is focused on how lignin is transported out of the fibers during washing and oxygen delignification of softwood sulphate pulp. This also includes studying the properties of the extracted lignin. Pulp and filtrate from Östrand's pulp mill have been used in parts of the work. It has been shown, among other things, that lignin that is released during oxygen delignification could have several interesting uses.

Uppsala University

At Uppsala University, research is focused on developing an advanced computer simulation of how a lignin molecule passes out through the fiber wall.

Overall, it is highly likely that some of the research results from the various works will be useful in SCA's future development projects.

Read more about Resource Smart Processes